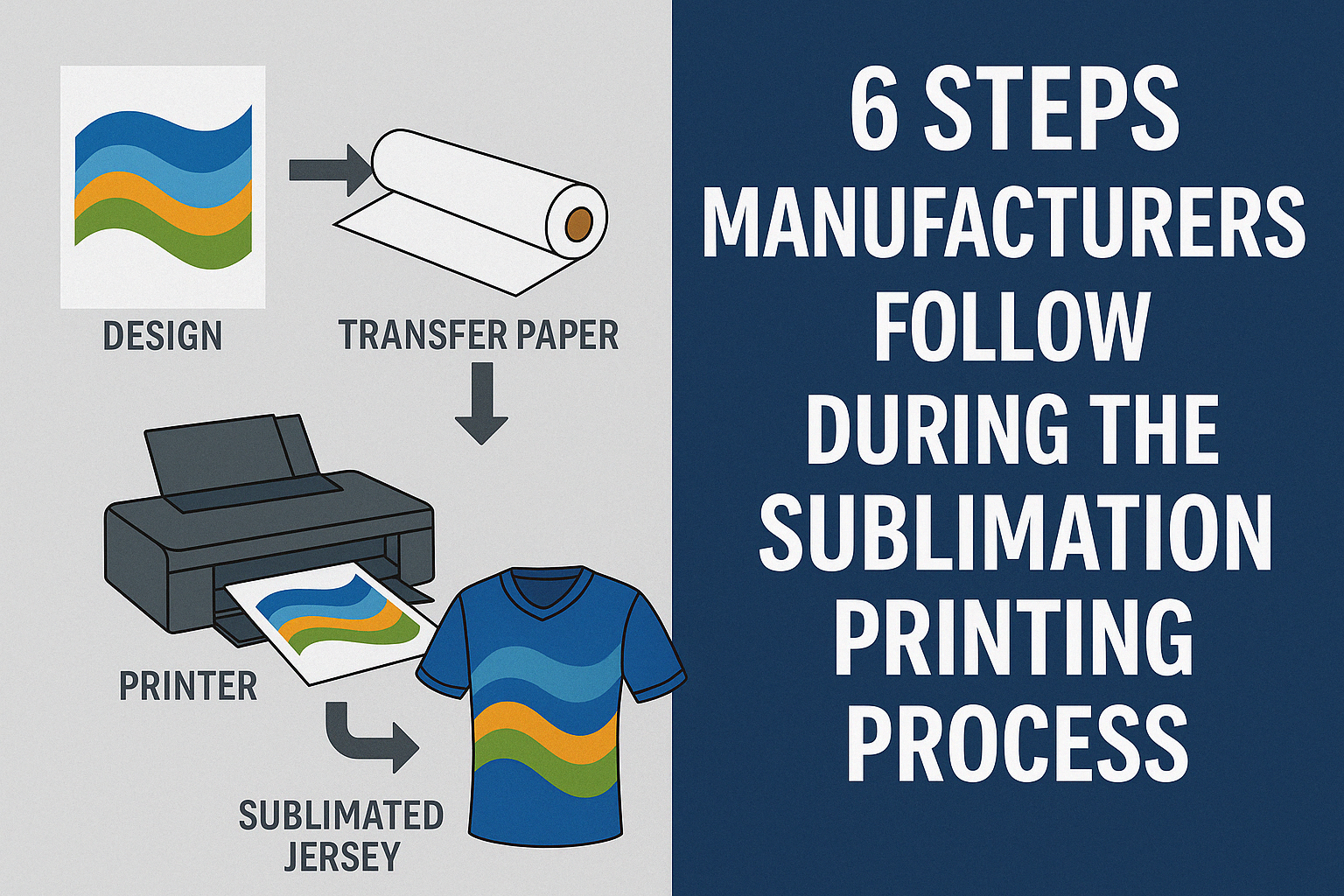

6 Steps Manufacturers Follow During the Sublimation Printing Process

Sublimation printing is a popular method for creating vibrant, long-lasting designs on polyester fabrics. As global interest in custom sportswear and personalized garments has soared, the demand for this technique has seen steady increases.

In fact, according to recent findings by printiepie.com, the global dye-sublimation apparel market was valued at USD 716.61 million in 2021 and is projected to reach USD 1,803.60 million by 2030, growing at a CAGR of 10.8%. This steady rise has made it important for designers, teamwear entrepreneurs, and manufacturers to understand the sublimation printing process thoroughly.

In this post, we will break down the six steps manufacturers commonly follow. Whether you are new to apparel production or looking to refine your existing workflows, understanding each step of the sublimation printing process can help determine the final look, feel, and durability of your products.

We will also discuss some key industry players, relevant software, and current trends shaping this market.

Understanding the Rapid Growth of the Sublimation Printing Process

The sublimation printing process has witnessed remarkable expansion due to its precision, color vibrancy, and versatility. According to smithers.com, the global market for dye-sublimation printing was valued at €10.1 billion in 2024 and could grow to €14.0 billion by 2029 at a CAGR of 6.6%.

This upward trend isn’t surprising—sublimation printing allows designs to fuse into polyester fabrics at the molecular level, resulting in a high-quality finish that doesn’t peel or crack.

Manufacturers are capitalizing on this growth in various ways. From small boutiques to major corporations, companies such as Epson, Mimaki, and Roland DG constantly innovate to make the sublimation printing process more efficient.

Printers that support higher production volume now come equipped with advanced color management features. Meanwhile, more specialized solutions like Sawgrass Print Manager ensure uniform color accuracy, making them popular choices among both beginners and experts. It all contributes to an ever-evolving market where creative flare meets cutting-edge technology.

Step 1: Artwork Preparation in the Sublimation Printing Process

The first step in the sublimation printing process involves developing clear, high-resolution artwork. This includes color-correct images, vector-based logos, and visually cohesive patterns.

For best results, many professionals rely on software like Adobe Photoshop or CorelDRAW to refine design elements before they ever reach the printer. Crisp lines, vibrant colors, and layout precision help ensure that the final product shines.

Beyond perfection in design, it’s essential to understand color profiles and resolution guidelines. Sublimation requires specialized inks and specialized printer drivers that demand consistent color management.

Software such as Sawgrass Print Manager or Epson Edge Print can help calibrate each design so that the printed colors match what you see on screen. Color accuracy is critical when serving sports teams or clubs with specific branding guidelines. Properly prepared artwork paves the way for a smoother production line in subsequent steps.

Step 2: Selecting the Right Paper and Ink in the Sublimation Printing Process

Once the artwork is finalized, the next step in the sublimation printing process is choosing the correct transfer paper and ink. Manufacturers often select transfer papers specifically made for dye-sublimation because these papers can hold the ink in a way that gives the best color release. Papers that boast fast-dry technology allow for quicker printing times and sharper details.

When it comes to inks, options like Sawgrass Sublijet inks or Epson dye-sublimation inks are commonly used for their proven reliability. Proper ink choice ensures high-resolution prints and color consistency across multiple production runs.

This consistency can be essential for brands that order large quantities of jerseys, tops, or custom uniforms. If your inks fail to match brand colors or fade too quickly, the entire production run may be compromised.

Therefore, manufacturers often source their paper and ink from reputable brands to maintain the durability and vibrancy that distinguish sublimation printing from other techniques.

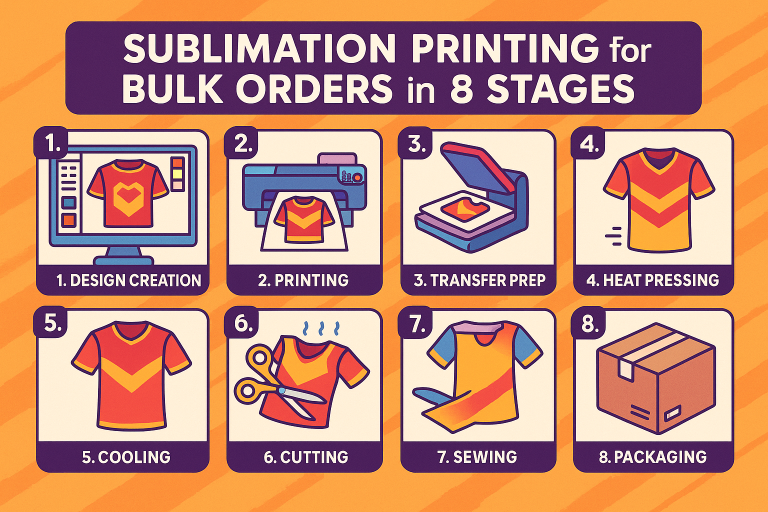

Steps 3 and 4: Printing and Heat Transfer for the Sublimation Printing Process

Once design preparation and materials are ready, it’s time for Steps 3 and 4 of the sublimation printing process: printing onto the transfer paper and applying heat to the substrate.

Printing on Transfer Paper

• The printing stage uses specialized dye-sublimation printers made by companies such as Mimaki or Roland DG. These printers heat the ink slightly so it adheres onto the transfer paper in a mirrored fashion.

• During this stage, software like Wasatch SoftRIP or Epson Edge Print can fine-tune color profiles and optimize print quality.

• Fespa.com notes that dye-sublimation printing accounts for nearly 50% of all digital textile prints across wide-format and apparel, highlighting the importance of investing in robust printing tools.

Applying Heat

• After printing, the transfer paper is placed onto a polyester-based fabric or other coated substrate.

• A heat press machine then applies both high temperature (usually around 400°F or 204°C) and pressure, turning the ink from a solid directly into a gas.

• This gaseous ink penetrates the fibers of the fabric, bonding permanently with the material.

• The result is a vibrant, durable image that won’t peel or crack over time.

By understanding and controlling these printing and heat application stages, manufacturers ensure that every garment meets the client’s expectations. Miscalibration in temperature, time, or pressure can lead to color shifts or blurred designs, underlining the importance of careful execution.

Steps 5 and 6 and Key Tools for Dye-Sublimation Success

The final two steps complete the sublimation printing process by focusing on cooling and quality assurance. Then, we’ll look at some resources and trends that can support continuous improvement in dye-sublimation.

Step 5: Cooling and Finishing

After the heat press transfers the design onto the fabric, the material needs to cool. Proper cooling sets the dye in place. Some manufacturers speed up this phase by using blowing fans or specialized cooling systems.

Once cooled, the finished fabric may be cut, sewn, or further treated to achieve the desired final product—like a jersey, sports jacket, or custom bag. Efficient finishing processes help companies keep up with large orders while maintaining consistent results.

Step 6: Quality Control and Inspection

Quality control is the last stage of the sublimation printing process. Manufacturers check for color accuracy, alignment, and any imperfections. High turnovers are common in the sportswear sector, so a robust inspection routine helps detect misprints before they reach retailers or sports teams.

If a design’s colors appear off or text is misaligned, it’s more cost-effective to identify these issues early rather than reprint an entire production batch later.

Essential Tools and Resources

To streamline steps 5 and 6 and beyond, many manufacturers rely on project management software, quality checkpoints, and color measurement devices. For example, colorimeters or spectrophotometers ensure consistent color reproduction across different print runs.

Tools like Adobe Photoshop or CorelDRAW enable designers to adjust and correct any identified issues quickly. While the majority of the heavy lifting in dye-sublimation happens at the printer and heat press, it’s these finishing and quality assessments that make for top-tier apparel.

Industry Players and the Push for Quality

Leading companies such as Seiko Epson Corporation, Agfa-Gevaert Group, and Mitsubishi Electric Corporation focus heavily on research and development. They aim to produce printers that can handle higher volumes without sacrificing print quality.

For teamwear, it’s vital to replicate the exact color palette across multiple jersey sizes and variations. These large companies compete by offering solutions that streamline the entire sublimation workflow, making them go-to choices for commercial-scale operations.

To achieve consistent high quality, small brands also find value in specialized equipment like Sawgrass’s smaller-format printers. These machines are ideal for startups or businesses that don’t have the space for large industrial printers.

By carefully considering which tools match specific production needs, brands can find the right balance between quality, speed, and cost.

Recent Trends Shaping the Market

- Sustainability: Eco-friendly practices are at the forefront, with the dye-sublimation process already recognized for using less water and energy compared to many other printing methods.

- Faster Turnaround Times: Demand from consumers for quicker delivery has led manufacturers to invest in high-speed printers.

- Enhanced Color Management Systems: Software solutions like Wasatch SoftRIP or Epson Edge Print help achieve consistent color results, essential for brand-driven teamwear and retail orders.

- Personalization Boom: As more people desire one-of-a-kind garments, sublimation is poised to capture a bigger market share, especially in the sports uniform and activewear categories.

These trends also reflect the data from printiepie.com indicative of at least 10% annual growth in the dye-sublimation market over the last decade. The technology’s ability to produce vivid, long-lasting prints continues to draw in sports teams, brands, and even everyday consumers looking to customize their clothing.

Conclusion

By understanding the six main steps, designers, teamwear entrepreneurs, and manufacturers can work more efficiently and consistently. Today’s market statistics—such as the global dye-sublimation printing sector growing to €14.0 billion by 2029—underscore just how integral this process has become.

When you step back and assess each stage of the sublimation printing process, you see a system perfectly suited for performance apparel and custom teamwear. Vibrant, highly durable prints elevate brand identity and athletic performance alike.

Whether you rely on software resources like CorelDRAW or Sawgrass Print Manager, or you invest in printers from key players such as Epson or Roland DG, the ingredients for success in the sublimation printing process are at your fingertips. As the industry continues to expand, taking the time to refine each step can ensure your brand stands out in a crowd hungry for quality, speed, and sustainability.

If you are wondering whether this technique is right for your next collection or team uniform, remember that the sublimation printing process excels in both aesthetic appeal and functionality.

By following the six steps, from artwork creation to finishing and final inspection, you can deliver products that match the growing consumer expectations for vibrant, eco-friendly, and durable sportswear.