Step-by-Step Breakdown of the Sublimation Printing Process for Sportswear

Sports teams, athletic brands, and even local leagues often look for high-quality uniforms that are vibrant, comfortable, and long-lasting. This is where the sublimation printing process shines.

In recent years, global demand for dye sublimation has grown swiftly—reaching a market size of USD 16 billion in 2023 and projected to soar to USD 29 billion by 2032.

With so much momentum behind dye sublimation, it’s clear that understanding this specialized technology can give sportswear businesses a real edge. In this post, we’ll walk through each stage of the sublimation printing process.

We’ll also cover the tools needed, how to prepare designs, and even why sustainability and customization are driving market growth.

Understanding the Sublimation Printing Process in Sportswear

The sublimation printing process is a method of transferring inks onto polyester fabrics using heat and pressure. Because polyester is so common in athletic clothing, sublimation is an ideal fit for producing sharp, full-color images that are also resistant to wear and tear. The process differs from traditional screen printing in that the dye actually bonds with the fibers, creating prints that won’t crack or peel.

According to industry research, more than 4.6 billion square meters of polyester fabric were printed using dye sublimation in 2023 alone. This method makes it possible for creative brands to produce everything from simple logos to full jersey designs with vibrant colors.

Whether you’re a manufacturer or a teamwear entrepreneur, knowing how sublimation works can help improve product quality and brand value.

Key Equipment and Materials in the Sublimation Printing Process

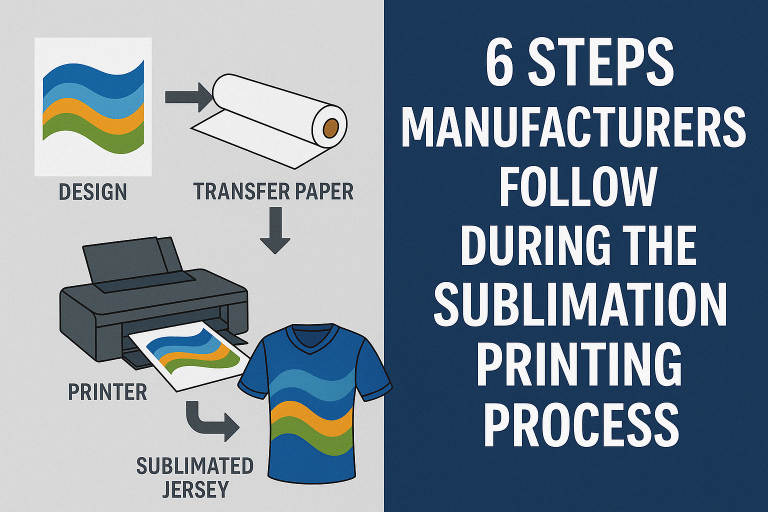

Before you start any sublimation printing process, you need the right equipment and materials. Below is a quick look at the essentials:

- Printer and Ink: A dye sublimation printer from companies like Seiko Epson Corporation, Mimaki Engineering, or Roland DG is the main piece of hardware. These printers use specialized inks that turn into gas under heat.

- Transfer Paper: This coated paper holds the printed design and releases the ink when heated.

- Polyester Substrate: Sublimation ink adheres best to polyester fibers, making it the go-to fabric for sportswear.

- Heat Press: A machine that applies both heat and pressure to transfer the design from the paper onto the fabric.

- Color Management Software: Tools like Adobe Photoshop, Sawgrass Print Manager, or Wasatch SoftRIP help ensure accurate colors when prepping your artwork.

Thanks to innovations from tech leaders such as HP Inc. and Kornit Digital Ltd., dye sublimation printers have become faster and more user-friendly. Some even incorporate AI and IoT capabilities for real-time performance checks.

Prepping Designs for the Sublimation Printing Process

Design preparation plays a big role in the sublimation printing process. Even the best printers and heat presses can’t fix a poor design. Below are two main steps to consider:

Color Accuracy and Proofing

For sportswear, brand colors, team logos, and name customization must be precise. Software such as CorelDRAW or Adobe Photoshop allows you to create high-resolution graphics with color profiles designed specifically for sublimation.

Color management is crucial because once ink fuses into the fabric, there’s no easy way to correct mistakes. Specialized software, like Epson Edge Print or Sawgrass Print Manager, can further refine the hues so that printed colors match what’s on your screen.

Design Layout and Sizing

Sportswear often demands well-placed details such as sponsor logos, numbers, and player names. Ensure your design template is aligned with the actual garment pattern. For instance, a jersey’s shoulder graphics should align correctly once sewn together.

Many print shops use CAD or vector files to map out each panel of the clothing item, making certain the final look is consistent after production. Also, remember that sublimation results are more vibrant on white or light fabrics, which is why most tech-lovers in the sportswear industry favor white polyester blanks.

Conducting the Sublimation Printing Process: Heat Transfer and Finishing

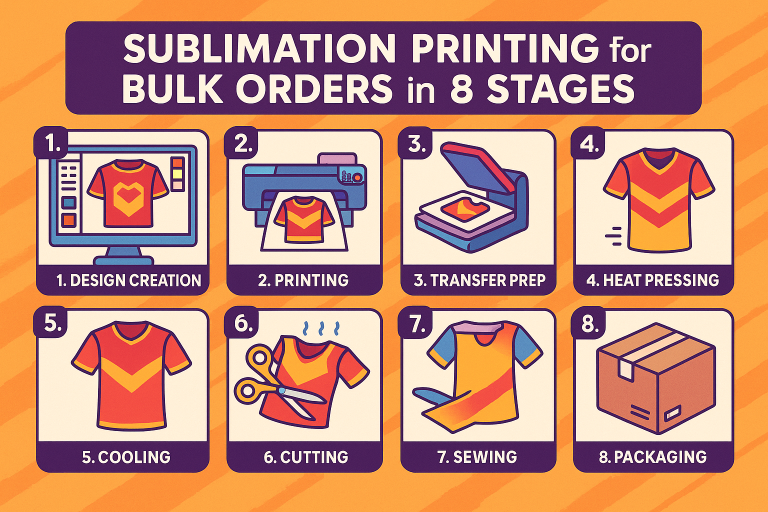

Now we’ve reached the heart of the sublimation printing process, which involves transferring your custom design onto the polyester fabric:

Transfer and Heat Pressing

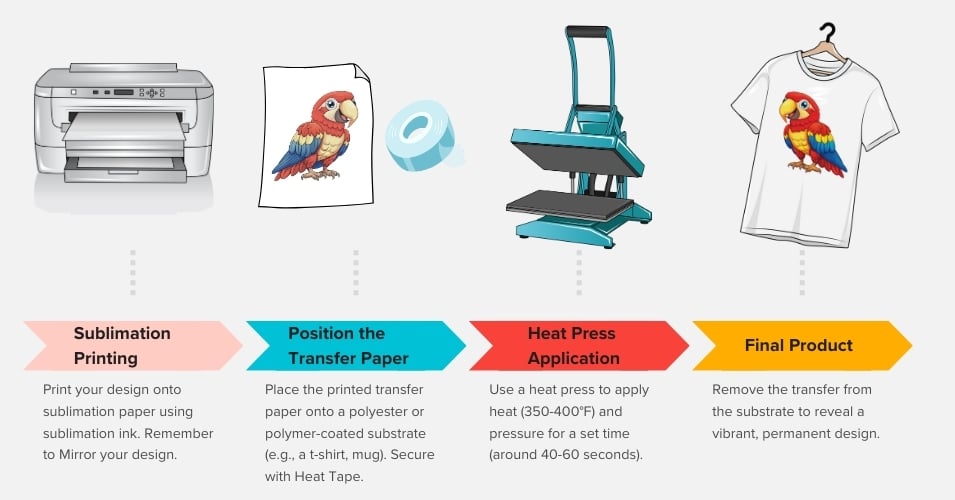

- Print and Position: First, you print your design onto sublimation transfer paper using your dedicated printer and dye sublimation inks.

- Align Your Fabric: Make sure your polyester garment or fabric panel is free of wrinkles and moisture. Even a small crease can create a flawed print.

- Apply Heat and Pressure: A heat press, usually set between 375°F to 400°F (190°C to 205°C), applies pressure for around 30 to 60 seconds. During this step, the dye on the transfer paper turns into a gas, bonding with the polyester fibers.

- Remove the Transfer Paper: Let the fabric cool slightly and carefully peel off the paper. You should see a crisp, vibrant design embedded right into the material.

When you’re done, the design becomes part of the garment itself. Unlike surface-level coatings, these inks don’t sit on top. This makes the design flexible, vivid, and less prone to fading.

Quality Control and Final Touches

After heat pressing, many manufacturers quickly check for color accuracy and alignment to catch errors early. Some might run a gentle wash test on sample pieces to confirm the print won’t fade or peel.

Because about 77.8% of the sublimation printing market is dedicated to apparel—and sportswear is a big slice of that—ensuring top-notch results is crucial. The garment is then sewn together if you’re using pre-cut panels, or if you’re printing on a finished piece, it may go for final packaging or labeling.

Why the Sublimation Printing Process Dominates Sportswear Production

Sublimation printing is the industry favorite for teamwear, jerseys, and other athletic apparel. Below are a few reasons why it has become so dominant:

- Durability: The dye molecules fuse with the polyester fabric, leading to vibrant prints that can withstand heavy workouts, repeated washing, and regular wear.

- Customization: From local leagues to professional teams, sportswear often requires unique player names, numbers, and sponsor logos. The sublimation printing process allows for cost-effective customization, even for small batches. Manufacturers such as Sphere Sport specialize in this kind of customization, helping clubs and brands create fully branded teamwear at scale or in flexible quantities.

- Speed and Efficiency: With demand for short-run orders skyrocketing, high-speed dye sublimation printers can quickly produce one-off or limited-edition jerseys without lengthy setup. For instance, the global transfer dye sublimation printing segment earned USD 9,499.0 million in revenue in 2024 and is set to reach USD 17,453.0 million by 2030—proof of how quickly this flexible technology is advancing.

- Cost Considerations: While specialized inks and transfer papers might be pricier than traditional screen printing materials, the ability to print multiple colors at once often offsets costs. The final garments can be produced with fewer steps, and there’s minimal waste since you only print exactly what’s needed.

Additionally, many brands like Sawgrass Technologies, Inc. and Durst Group AG focus on sustainability. They’re developing eco-friendly inks and energy-efficient printing equipment. This green push reflects a broader apparel trend toward mindful production practices, especially in sportswear where heavy usage is common.

Conclusion

The sublimation printing process is more than just a buzzword—it’s a game-changer in sportswear design and production. From design preparation and color management to heat transfer and finishing, each step ensures high-quality output on polyester fabrics.

With an ever-growing demand for custom apparel—driven by personalization, advanced technology, and market projections nearing USD 29 billion by 2032—it’s clear why so many sportswear brands rely on the sublimation printing process to thrive. Whether you’re a designer aiming for perfect color accuracy or a manufacturer hoping to scale quickly, understanding these steps can elevate your apparel line season after season.