How Does Sublimation Printing Work for Small Teamwear Brands with Low MOQs

Sublimation printing offers small teamwear brands a fast and highly customizable way to bring creative apparel ideas to life. With minimal inventory risk and lower minimum order quantities (MOQs), many entrepreneurs and small-scale manufacturers are exploring how does sublimation printing work to elevate their team uniforms while keeping costs under control.

In this post, we will break down the entire process, highlight industry trends, offer practical tools, and show you exactly why this printing method stands out for small sportswear operations.

Why Sublimation Matters for Small Teamwear Brands

Small teamwear brands often need to deliver eye-catching designs but can’t commit to large production runs. Traditional printing methods—like screen printing—usually demand high MOQs and don’t always offer the same design flexibility. That’s where sublimation printing comes in.

It uses special dyes and a heat press to transfer artwork onto polyester-based materials. This process results in designs that won’t peel or fade easily, making them ideal for athletic wear.

Beyond strong durability, sublimation printing allows for vivid and detailed artwork. Because the inks bond directly with polyester fabric, the final prints have bold colors that are perfect for sports jerseys, shorts, and warm-up jackets.

With the global sublimation printing market projected to reach around $6 billion by 2025, small brands are seizing the opportunity to tap into a growing trend.

A big advantage for smaller operations is the ability to produce short runs without major setup costs. According to industry data, the rise of e-commerce and on-demand customization has reshaped supply chains, letting small producers print exactly what they need, when they need it.

Instead of only catering to large corporate orders, sublimation helps niche teamwear entrepreneurs capture holiday spikes or special event demands without holding large stock.

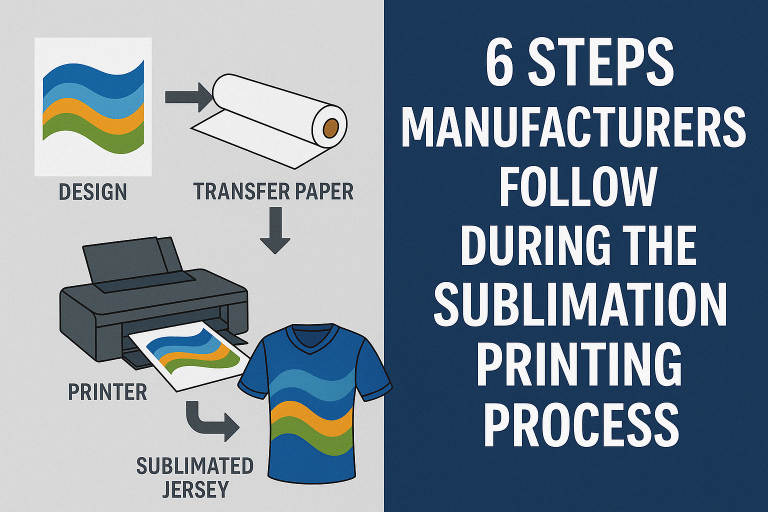

How Does Sublimation Printing Work: An Overview

To understand how does sublimation printing work, think of it as a heat-based process that uses printed transfer paper and specialized ink. Traditional printers use liquid inks that just sit on top of the fabric, but sublimation inks become a gas when heated. When pressed onto polyester at high temperatures, these inks fuse with the material, resulting in vibrant, long-lasting graphics.

Here are a few key highlights of how sublimation printing has become more accessible:

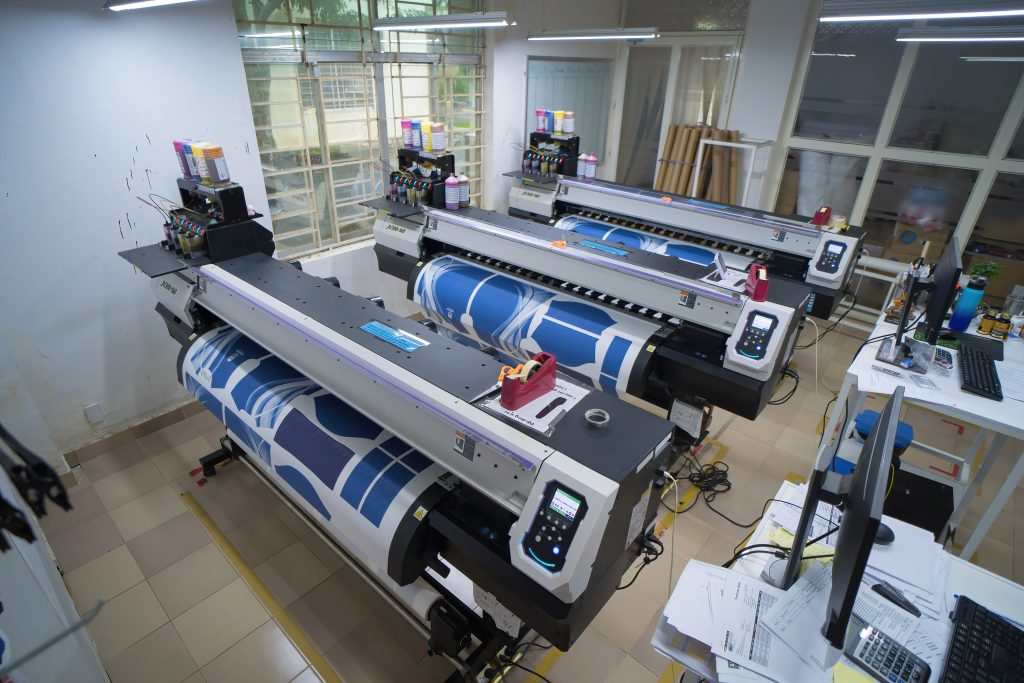

- Growing Market: With the global sublimation market expected to reach $28–$29 billion by 2030, brands of all sizes are adopting this technique. Companies like Epson, Roland DGA, and Mimaki are releasing more affordable printers designed for small-batch production.

- Ease of Customization: Sublimation doesn’t require multiple screens or lengthy setups. Designers can change names, numbers, or artwork quickly using software like Adobe Illustrator, CorelDRAW, or Sawgrass CreativeStudio.

- Sustainability: Around 60% of consumers prefer environmentally friendly brands. Sublimation is relatively low-waste compared to methods that require lots of water or harsh chemicals. It also pairs well with recycled polyester fabrics, responding to the push for more eco-friendly materials.

By blending convenience, creativity, and planet-friendly practices, sublimation stands out for teams who want smaller runs without sacrificing design quality.

How Does Sublimation Printing Work for Low MOQs

Small volumes can be a real challenge in apparel production. Traditional factories prefer large orders, and startup costs often won’t make sense for runs of just a few dozen pieces. However, now that e-commerce personalization is on the rise, there’s an increased demand for short-run capabilities. Here’s how sublimation fills that gap:

Low Risk with Fewer Units

When you’re ordering just 20 jerseys for a local soccer club, you don’t want leftover inventory piling up in your garage. Sublimation’s minimal setup fees allow brands to produce what’s needed and move on. Suppliers like Heat Press Nation and Stahls’ also offer heat press machines in a range of sizes, so you can scale up or down without a massive cash outlay.

Quick Changes and Prototypes

It’s normal for small teams to revise their designs often. With sublimation, you can swiftly adjust artwork files before each print run. If you need a jersey with a new sponsor logo, simply update the design and print again—no need to remake multiple costly screens.

Flexible Supply Chains

Online platforms and local printing partners have adapted to the print-on-demand model. With the rise of e-commerce, businesses can manage direct-to-customer sales, limiting wasted inventory. Companies like Sawgrass Technologies specialize in equipment for small teams, ensuring you can print on demand without ordering huge supplies of blank stock.

Overall, how does sublimation printing work to solve low MOQ challenges? It combines software-driven designs, specialized ink technology, and heat transfer methods to produce high-quality items in tiny batches. This helps small teamwear brands stay lean, adapt quickly, and fulfill custom requests without ballooning costs.

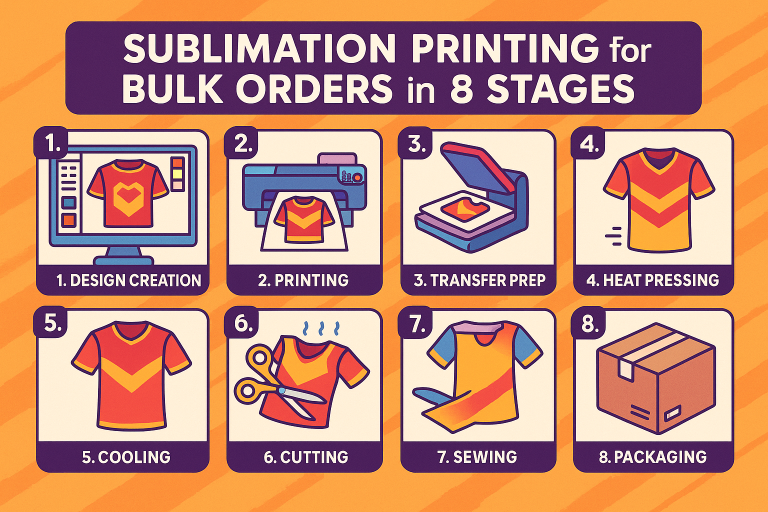

How Does Sublimation Printing Work: Step-by-Step Breakdown

When people ask “how does sublimation printing work” in practice, they are often looking for a quick roadmap. Though the overall concept is simple, the details matter for consistent, professional results.

- Design Phase

• Use a graphics program: Adobe Illustrator, CorelDRAW, or Sawgrass CreativeStudio help you create vector-based artwork for crisp lines and accurate colors.

• Prepare files: Ensure your design fits the garment’s template. Account for seams and safe margins so vital elements don’t get cut off. - Printing Your Transfer

• Sublimation printer: Load it with special dye-sublimation ink. Roland DGA, Mimaki, and Epson offer models that match various budget levels.

• Transfer paper: Print the design in reverse on sublimation transfer paper. The paper holds the ink until you apply heat. - Heat Press Setup

• Temperature and time: A typical polyester sublimation run needs about 400°F (204°C) for 30-60 seconds. Exact settings vary by fabric.

• Position the garment: Lay your polyester garment flat on the press, place the printed transfer paper facedown on the area you want printed. - The Transfer Process

• Sublimation magic: Under heat and pressure, the ink on the paper vaporizes and fuses into the melting polyester fibers.

• Wait for cooldown: After pressing, let the garment cool. The design is now part of the fabric and won’t crack or peel. - Post-Press Inspection

• Check color accuracy: Vibrant, evenly toned prints indicate a successful transfer.

• Final curing (if needed): Some brands lightly heat the printed item again or wash test it to confirm durability.

Throughout these steps, consistency in heat, pressure, and printing settings is key. If something’s off, the final result may look faded or misaligned. With practice and the right equipment, small operators can achieve professional-level results.

How Does Sublimation Printing Work: Best Tools and Sustainability

Sublimation printing isn’t just about transferring design to fabric. It’s also about choosing the right tools, software, and resources that align with your brand values—especially if sustainability is a priority.

Essential Tools and Software

• Printers: Sawgrass Technologies is known for user-friendly setups aimed at small businesses. Epson and Roland DGA also offer entry-level models for short runs.

• Design Software: Adobe Illustrator and CorelDRAW are popular for vector-based graphics. For beginners, Canva or Affinity Designer can handle less complex work.

• Heat Press Machine: Stahls’ and Heat Press Nation provide press machines catering to different budgets. Look for one that offers reliable pressure and consistent heat distribution.

• Blanks and Fabrics: Joto Imaging Supplies and Unisub offer a wide variety of sublimation-ready blanks, from mugs to performance jerseys. If you want to print on garments, stick with polyester or polyester-blend fabrics.

Embracing Eco-Friendly Approaches

Sustainability is more than just a buzzword. Research shows that about 60% of consumers prefer brands that support green initiatives. Sublimation printing already uses less water than traditional dye processes, but you can go further by:

- Choosing Recycled Polyester

Look for suppliers offering fabrics made from plastic bottles or other reclaimed sources. These work with dye-sublimation inks while reducing the environmental impact. - Minimizing Waste

Print only after receiving orders. Adopting a print-on-demand model cuts overproduction and leftover stock. This aligns perfectly with sublimation’s flexibility. - Exploring New Inks

Newer inks and heat transfer methods strive for lower VOC emissions. Check product descriptions or consult with manufacturers like Mimaki, who are investing in greener ink formulas.

Combining the right tools with an eco-friendly mindset helps small teamwear brands stay competitive, connect with conscious consumers, and keep production lean. As global sublimation printing grows at a rate of 8.6% annually, your brand can thrive by adopting sustainable practices early.

Conclusion and Future Outlook

Understanding how does sublimation printing work is no longer just for massive clothing factories. With more affordable printers, improved software, and rising consumer desire for customized apparel, small teamwear brands are embracing sublimation’s versatility. You don’t need to produce huge inventories to compete with the big players.

Instead, sublimation printing allows you to cater to teams seeking vibrant and durable uniforms—often with rapid turnaround times. Small teamwear providers such as Edgy Sport show how flexible MOQs and sublimation technology can help local clubs and niche brands compete without overextending on inventory.

Recent trends, including AI-assisted design, print-on-demand services, and hybrid printing techniques, signal even more exciting developments ahead. By staying informed and investing in the right tools—from heat presses to eco-friendly polyester—your small brand can deliver stand-out products for local clubs, niche sports leagues, and athletic enthusiasts everywhere.

Now that you know how does sublimation printing work, you can gain a competitive edge in the world of custom sportswear with smaller MOQs and higher creativity.