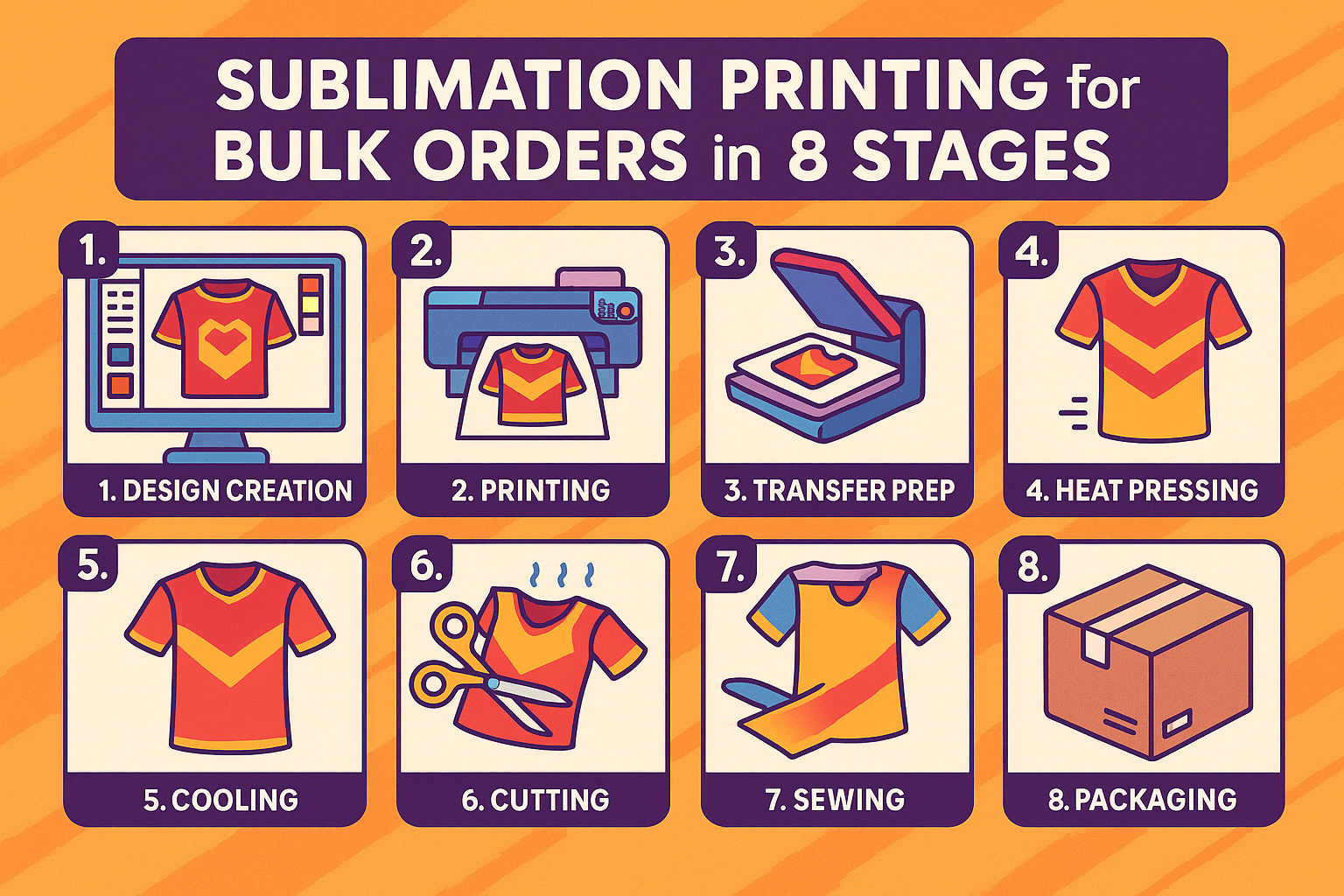

How Do You Do Sublimation Printing for Bulk Orders in 8 Key Stages

Introduction

Sublimation printing is a method that uses heat and special inks to transfer designs onto polyester-based fabrics and other suitable materials. If you’re wondering, “how do you do sublimation printing?” you’re in good company. The global sublimation printing market is booming, with its value projected to grow from around USD 16 billion in 2023 to nearly USD 29 billion by 2032, according to recent research. This rise is driven by increasing demand for customized sportswear, branded team uniforms, and eco-friendly printing solutions.

In this post, we’ll explore exactly how do you do sublimation printing for bulk orders in eight key stages. From design preparation and color management to shipping the final products, these steps will help you produce high-quality, long-lasting prints. Dye-sublimation printing bonds the ink to polyester substrates, ensuring vibrant colors and durability. If you follow these stages, you’ll be well-equipped to handle larger orders efficiently while maintaining professional results.

How Do You Do Sublimation Printing: Stages 1–3

Bulk sublimation printing involves organizational planning, design setup, and precise material selection. Below are the first three stages to get you started.

Stage 1: Design Preparation and Layout

Proper design preparation is crucial for any sublimation project, especially for large orders. Start by using graphic software such as Adobe Photoshop or CorelDRAW. These tools enable you to create or refine your images and ensure they have high resolution and sharp details. Keeping designs clear is vital because once you transfer them onto fabric or other materials, you want them to remain crisp and easily visible.

- High-Resolution Designs: Ensure you’re working at 300 DPI (dots per inch) or higher. This helps the final print look vibrant and not pixelated.

- Vector or Raster: Vector graphics (e.g., in CorelDRAW) are easier to resize for large or small runs without quality loss.

- File Organization: Label files with version numbers and set up a consistent naming structure to avoid mix-ups in big orders.

Remember, roughly 54% of apparel manufacturers reported an increase in ROI after switching to sublimation production, highlighting the importance of a solid design flow in reducing errors and reprints. Software like Sawgrass Print Manager can also assist with color management and layout optimization.

Stage 2: Sourcing Materials and Tools

Once your designs are ready, the next step is to gather the materials needed. Most sublimation projects use polyester-based fabrics because the dye bonds deeply with polyester fibers, producing bright and long-lasting results. Around 57% of new sublimated apparel launches feature eco-friendly polyester blends, which shows the industry’s move toward greener and more sustainable options.

- Choosing the Right Printer: Leading brands like Seiko Epson Corporation, Mimaki, and Roland DGA offer a range of dye-sublimation printers. For large orders, look for printers that can handle higher throughput, maintain color consistency, and accommodate wide-format rolls of sublimation paper.

- Sublimation Paper: High-quality sublimation paper ensures that inks don’t bleed or fade too quickly before transfer. With the global sublimation paper market expected to reach USD 8.2 billion by 2032, it’s clear this component plays a crucial role in achieving top-notch prints.

- Heat Press: You’ll need an industrial-size heat press if you’re aiming for mass production. This ensures consistent temperatures and even pressure, both critical for transferring dyes effectively onto large batches of fabric.

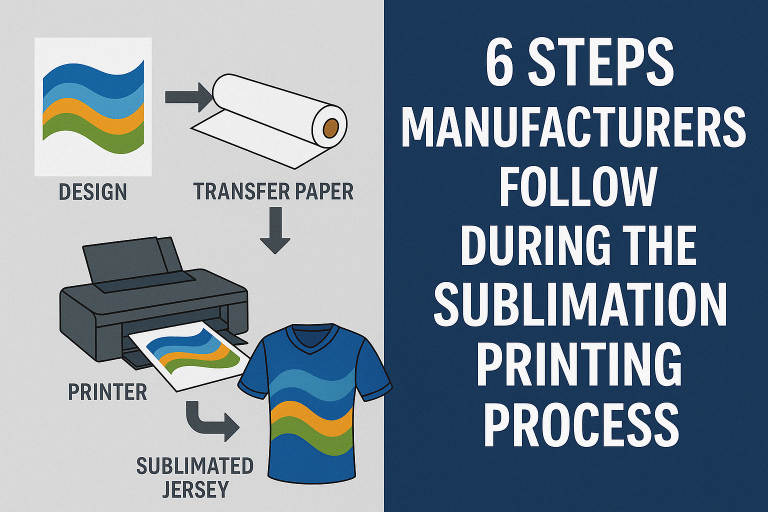

Stage 3: Printer Setup and Color Management

Color management is a significant factor in how do you do sublimation printing effectively. Sublimation projects can fail if the colors you see on-screen don’t match the final prints. This mismatch typically occurs due to differences in printer settings, ink formulations, and substrate characteristics. By using RIP software like Wasatch SoftRIP or Epson Edge Print, you can ensure color consistency across multiple prints.

- Ink Settings: Use recommended ink profiles from the printer manufacturer or the ink provider. This helps maintain vibrant and accurate colors, particularly for large runs.

- Test Prints: Test small batches or single pieces before moving to full-scale production. This quality check can catch color errors and inconsistencies quickly.

Proper color management can help you avoid wasted materials and rejections. Considering that over 63% of fashion brands embraced new sublimated products in 2023 and 2024, color fidelity is what separates a professional brand from the rest.

How Do You Do Sublimation Printing: Stages 4–5

Once you’ve nailed down design, materials, and color consistency, the next phases focus on the sublimation transfer process and immediate post-transfer checks.

Stage 4: Sublimation Transfer and Pressing

Transferring your design from sublimation paper to the polyester substrate is the heart of how do you do sublimation printing. This stage makes or breaks the final outcome. Generally, the steps for transferring are:

- Position the Design: Place the printed sublimation paper onto the fabric, ensuring proper alignment and a snug fit without creases.

- Heat Press Settings: Typical settings for polyester fabric involve temperatures around 380–400°F (193–204°C) for 35–60 seconds. However, different materials might need slightly varied settings.

- Apply Pressure: Move the heat press down to start the transfer. Even pressure across the item is key to consistent results.

The global sportswear market, valued at over $180 billion in 2023, relies heavily on dye-sublimation printing for personalized team uniforms. A well-executed transfer, free of wrinkles or color shifts, is essential for retaining brand quality and meeting customer satisfaction.

Stage 5: Immediate Post-Transfer Check

Once the heat press cycle finishes, carefully lift the top platen and remove the sublimation paper. Inspect the fabric to confirm the design has transferred properly:

- Color Assessment: Are the colors vibrant and true to the original design?

- Alignment and Smudges: Check the edges and corners. Mistakes such as ghost images or smudging often happen if the paper shifts during pressing.

- Fabric Quality: Polyester blends can sometimes show a slight gloss change after pressing due to the heat. Ensure this doesn’t affect the look or feel of the garment.

Making quick checks at this stage keeps small issues from becoming major problems. It’s simpler to discard or correct a few errors now than to discover them after a hundred garments have passed through the press.

How Do You Do Sublimation Printing: Stages 6–8

As you wrap up the technical steps of your bulk sublimation project, it’s important to handle quality control, packaging, and potential reordering to maintain a smooth operation.

Stage 6: Quality Control and Finishing

Quality control involves more than just color checks. It also includes inspecting seams, hems, and any additional elements like zippers or logos. According to data, dye-sub printed soft signage has captured 48% of the global visual communication market, largely because of consistent quality and resistance to weather or fading. Aim for similar consistency in your apparel items.

- Trimming and Threads: Inspect edges for stray threads, dusty surfaces, or untrimmed fabrics, and remove them.

- Final Heat Checks: For certain products, you might do a quick post-press heat fix to ensure the design won’t fade or peel.

Stage 7: Inventory and Reorders

Bulk orders often mean you’ll stock up or ship large quantities at once. However, keep your designs and color profiles organized for future reorders. Over 72% of apparel-focused investors now prioritize technology-based customization startups, indicating the demand for repeated, consistent production.

- Digital File Management: Save final design files in secure locations. Having them ready in the correct format accelerates reorders.

- Stock Assessment: Keep track of leftover materials—extra sublimation paper, ink, or polyester fabric. This not only saves money but also helps forecast future orders.

Stage 8: Packaging and Shipment

The last stage involves packaging and sending your finalized garments to customers or retail stores. Proper packaging protects the prints and presents a professional image. Some companies add branded tags or instruction labels (e.g., wash in cold water, do not bleach) to help users preserve the print quality.

- Labeling and Branding: Branded packaging increases perceived value and sets you apart, just as Under Armour and Gildan do with their custom-labeled products.

- Shipping and Tracking: Choose a reliable courier to reduce damage and delays. Bulk shipments might cost less per garment, so consider negotiating with shipping providers.

Additional Tips and Tools

With new trends in eco-friendly inks and the integration of e-commerce platforms, the sublimation printing landscape continues to evolve. Here are a few extra tips:

- Eco-Conscious Production: Increasingly, businesses are seeking water-based inks and more energy-efficient printers to align with sustainability goals. This is a winning approach, given polyester can be recycled more easily and water-based inks reduce environmental impact.

- On-Demand Printing: E-commerce integration allows consumers to customize designs online, which you can fulfill using sublimation printing technology. Many print shops now operate on-demand, avoiding overproduction and cutting storage costs.

- Software Upgrades: Advanced RIP software like Wasatch SoftRIP helps with color consistency across large runs. Also, Sawgrass Print Manager ensures your ink usage stays efficient.

- Partnerships: Collaborate with experienced brands like Mimaki Engineering Co. or HP Development Company to gain access to better technical support and guidance when scaling up.

Conclusion

Ultimately, the answer to “how do you do sublimation printing?” lies in following these eight structured stages. By focusing on design preparation, color management, rigorous quality control, and professional packaging, you’ll be well-equipped to handle large orders.The dye-sublimation market continues to grow—valued at $14.9 billion in 2024 and expected to climb with a CAGR of 11.3% between 2025 and 2030—so now is the perfect time to refine your workflow for bulk sublimation jobs.

Whether you’re a small design studio or a massive sportswear manufacturer, your approach to how do you do sublimation printing sets your brand apart. Implementing these stages systematically ensures each garment meets professional standards, from color accuracy to durability and overall presentation. Keep an eye on emerging technologies, eco-friendly practices, and on-demand customization trends to maintain a competitive edge in this rapidly evolving industry.