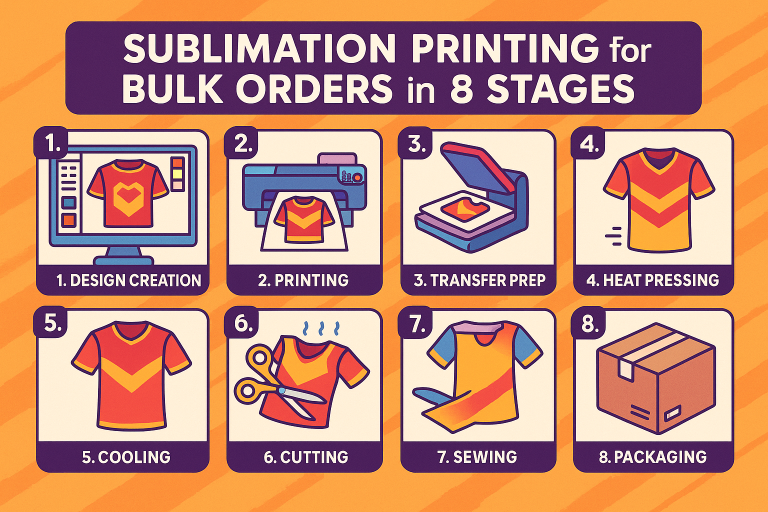

Step-by-Step Look at the Sublimation Printing Process in Small-Batch Production

Many custom apparel brands, sportswear designers, and entrepreneurs rely on the sublimation printing process to bring vibrant, long-lasting designs to life. This technology allows for high-quality, full-color prints on items like jerseys, jackets, and personalized accessories.

According to Zion Market Research, the global dye sublimation printing market is projected to grow from USD 16 billion in 2023 to USD 29 billion by 2032. The popularity of this method stems from its versatility, color accuracy, and durability—traits that are especially important for team uniforms and small-run apparel collections.

In this post, we’ll explore how the sublimation printing process works from start to finish and how small businesses can optimize each step. Whether you’re just beginning to design or ready to expand your production lines, this overview will help you better understand what goes into creating consistently vibrant garments.

Sublimation Printing Process: Preparing Your Design

Before you start transferring designs onto fabric, it’s important to set up well-planned design and color management workflows. The sublimation printing process demands precise color manipulation so that the final result on the fabric or substrate matches your creative vision. Here are two key starting points:

- Software Tools for Design

Popular programs like Adobe Photoshop and CorelDRAW help create, edit, and finalize your graphics. If you’re looking for user-friendly platforms, consider Canva as well. These tools let you manage color profiles, layer images correctly, and ensure the design is print-ready.

Some specialized software such as Sawgrass Print Manager can simplify your color calibration. This is critical in guaranteeing that your design’s red, for example, doesn’t turn into a pinkish or orange hue when transferred. - Color Management and Simplification

At an 8th grade reading level, think of color management as a simple matching game: your computer screen needs to “talk” the same language as your printer and your final fabric. For sublimation, a color profile must be consistent across these stages.

Color management ensures that your bright purples and neon greens look the same on the finished garment. Without it, you could end up with mismatched or dull prints.

Proper design and color prep save time and reduce costs in the long run. In 2023 alone, over 4.6 billion square meters of polyester fabrics were printed using dye sublimation, showing how widespread and competitive the industry has become. By streamlining your design phase, you’re positioning your brand for higher efficiency and customer satisfaction.

Sublimation Printing Process: Creating and Printing Your Transfers

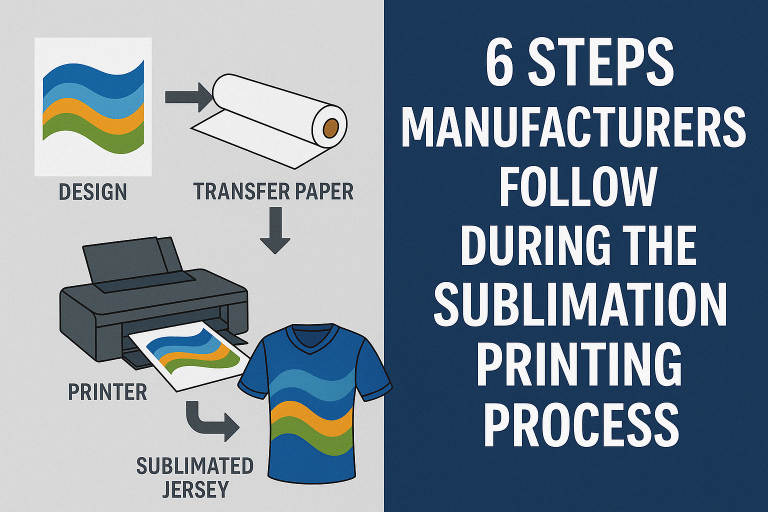

After you design your images, the next step involves printing them onto special transfer paper. This is where you select your printer, manage ink usage, and ensure print resolution accuracy.

- Choosing Your Printer and Ink

Many companies cater to small-batch production. Roland DG Corporation, Sawgrass Technologies, Inc., and Mutoh Industries Ltd. all produce equipment suitable for limited runs and niche apparel items. For instance, Sawgrass offers printers and inks optimized for custom apparel entrepreneurs.

Their items are designed for color vibrancy and consistent results, which is crucial for sports uniforms that need to look professional game after game. Additionally, the global dye sublimation printing ink market was valued at USD 716.61 million in 2021, and it’s projected to reach USD 1,803.60 million by 2030, signaling strong demand for specialized inks. Always verify your printer’s compatibility with the ink you plan to use to avoid clogs or inconsistent color output. - Printing to Transfer Paper

The transfer paper carries your printed design before it meets your final garment. In the sublimation printing process, this paper uses special coatings to hold onto the dye until it’s heated and pressed. Print resolution and paper quality go hand in hand: a sharper resolution allows for finer details on your final product.

Keep printing instructions handy. Each transfer paper type has recommended print settings. Following these guidelines—and ensuring the printed image is mirrored if required—minimizes mistakes. Once your designs are transferred successfully, you’ll be ready for the next stage: applying heat and pressure.

Sublimation Printing Process: Using the Heat Press

The heat press is where the magic happens. During this part of the sublimation printing process, the design on the transfer paper turns into a gas that bonds with polyester fibers, forming vibrant and permanent images on your garments.

- Heat and Pressure Essentials

Heat presses come in various sizes, from small 9×12 inch plates to large industrial presses. For small-batch production, a mid-size press often does the trick. The temperature settings, pressure, and dwell time are vital to a successful print. Most polyester-based fabrics require around 400°F (205°C) for 30-60 seconds at medium pressure. Always check your press manual for exact guidance.

When heat and pressure are applied, the dye on the transfer paper “sublimates,” or changes from a solid to a gas. This gas then seeps into the polyester fibers, creating a vibrant print. Once the press is released, the gas returns to a solid state, and your design is permanently embedded. - Selecting Suitable Materials

Sublimation printing works best on polyester fabrics or blends containing a high polyester percentage. This is because the dye bonds specifically to the polyester molecules. According to PrintiePie, apparel remains the leading sector for sublimation printing, making up almost 77.8% of the industry’s end-user market share.

Designers looking for unique products also use polyester-coated blanks, such as ceramic mugs or aluminum photo panels. Mugs, blankets, and other gifts saw a surge in sublimation popularity, with more than 90 million personalized items sold in 2023. Always verify that your chosen item is suitable for sublimation by checking for a polyester coating or label.

Sublimation Printing Process: Perfecting Small-Batch Runs

Small-batch production is ideal for customized sportswear, limited-edition merch, or on-demand personalized items. The sublimation printing process can be easily scaled up or down, making it popular among new brands and established factories alike.

- Workflow Optimization

Streamlining your workflow means ensuring each stage, from design to heat pressing, follows a consistent pattern. Use planning software or even a simple chart to track your garments. This keeps your brand from mixing up designs and ensures that color calibrations are reused effectively.

Companies like HP Inc. and Mimaki Engineering Co., Ltd. offer printers designed for efficiency, helping you stay productive on a smaller scale. Remember that frequent maintenance—like cleaning print heads—reduces downtime and protects against wasted ink. This benefits your bottom line, as every garment you produce should meet the quality your customers expect. - Building a Dependable Factory Pipeline

Small-run businesses often collaborate with local or regional partners for cutting, sewing, or distribution. Aligning with reliable collaborators guarantees consistent fabric quality and timely delivery.

If you aim to grow, consider adopting hybrid printing systems, which combine sublimation with other digital techniques, or explore expansions into new sectors like automotive textiles. Recent data from pmarketresearch.com shows that sublimated automotive textiles comprise 12% of the global automotive upholstery market in 2023, up from 8% two years ago. This growth highlights the flexibility of sublimation beyond sportswear.

Sustainability and Future Outlook

As global awareness of environmental impact increases, many organizations focus on making the apparel industry more sustainable. The sublimation printing process has several advantages here. It produces relatively little wastewater, uses less ink compared to some traditional methods, and is compatible with recycled or eco-friendly polyester materials.

- Trends Driving Sustainability

- Use of Recycled Materials: More brands are experimenting with recycled polyester in their garments. These materials work well with sublimation dyes and reduce plastic waste that might otherwise end up in landfills.

- AI Integration: Some printers use AI to monitor and adjust ink deposition in real time, optimizing efficiency and reducing misprints. This trend is expected to continue as the market grows.

- Hybrid Systems: Combining sublimation with direct-to-garment or other forms of digital printing allows shops to expand into multiple product categories. This helps reduce fabric waste because you can print what you need with minimal overruns.

- Forecasts and Beyond

The global dye-sublimation printing market size is projected to reach USD 25.18 billion by 2029, driven by a CAGR of 12.35%. Asia Pacific leads in revenue, expected to grow from USD 132.85 million in 2021 to USD 380.72 million by 2030. Many big players—Kornit Digital Ltd., Durst Group AG, and Ricoh Company, Ltd.—are focusing on product innovation that caters to both mass-scale and small-batch producers.

As the market widens, expect to see more resources and software like Silhouette Studio or Sawgrass Print Manager that cater specifically to creative entrepreneurs. Education is also expanding, with many tutorial blogs, online courses, and conferences helping small businesses harness the potential of sublimation printing.

Conclusion

The sublimation printing process has proven to be a flexible, efficient, and high-quality solution for custom apparel, sports uniforms, and even home décor items. From meticulous design and color management to heat press operation and small-batch logistics, each step is crucial for achieving vibrant results.

Keeping an eye on the market’s rapid growth, especially in regions like Asia Pacific, reveals that sublimation is one of the fastest-developing segments in textile printing technology.

Whether you’re a startup refining color accuracy or an established brand building a dependable production pipeline, the sublimation printing process can elevate both performance and brand impact. By staying informed about printing equipment, sustainable methods, and emerging technologies, you’ll be ready to bring out the best in every garment you produce.